Quality Module

QC

In an era where customer demands are diverse and quality is a key factor in consumer decision-making, quality control plays a vital role in managing the production process to ensure that products meet the required standards. The importance of quality control (QC) and the operational approaches are as follows:

1. Effective Quality Level Control

Effective quality control involves monitoring and managing the production process at every stage to ensure that the final product meets the required standards. This is achieved through the use of technology and tools to measure and track quality. Controlling quality levels helps ensure that consumers receive reliable products that meet the expected quality standards.

2. Improving Finished Product Output

Improving the output of finished products involves analyzing quality data and evaluating test results to identify issues and defects. These insights are then used to improve production processes and reduce errors, resulting in higher quality products that better align with customer expectations.

3. Quality Control Department Establishes Standardized Process Improvements

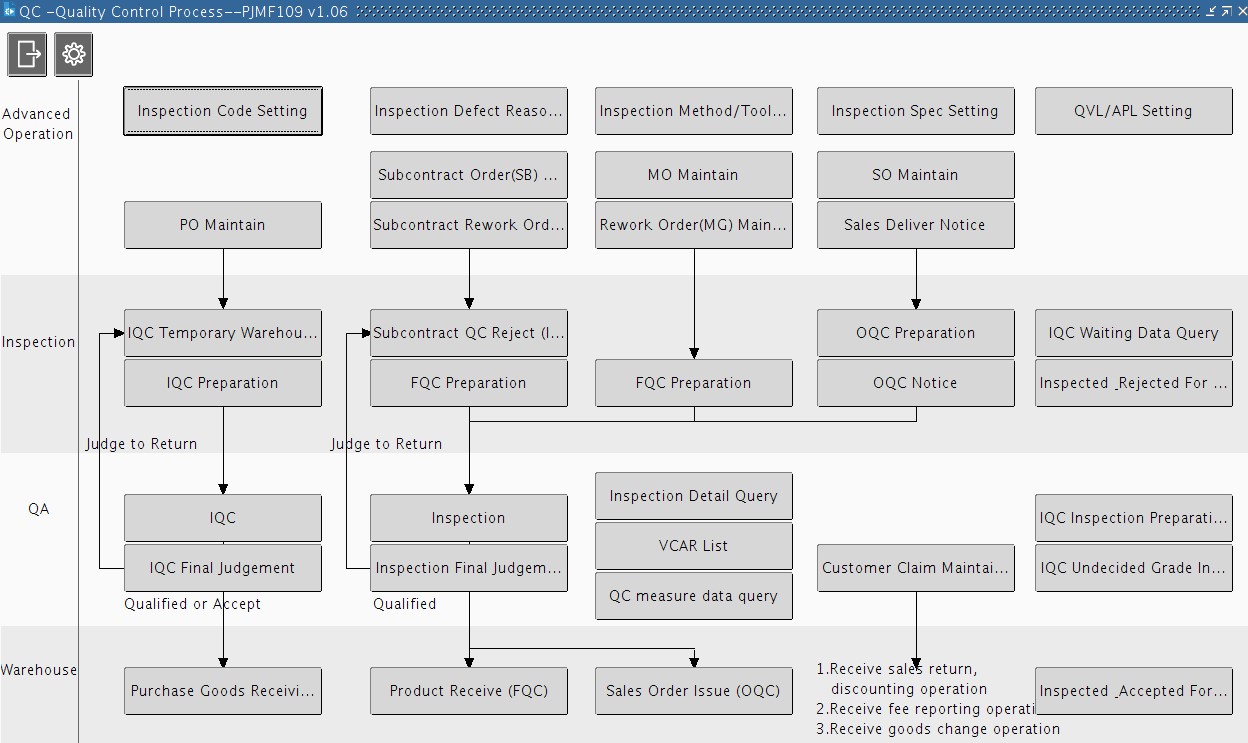

The quality control department plays a crucial role in defining standardized improvement processes. This ensures that production operations are efficient and compliant with the required quality standards.

Quality control (QC) is an essential process for successful product manufacturing. Consistent quality level control and improvements in finished product output are critical elements in ensuring that consumers receive products of high quality and standard.